- Fabricate Dye Sensitized Solar Cell using Natural Dyes

- Investigate a variety of different dyes and their effects on cell efficiency

- Develop cosensitized cells by mixing compatible dyes and comparing their performance

For my final year project of my BSc Physics degree, I fabricated solar cells using natural dyes extracted from plants, fruits and vegetables. The motivation being the project was to investigate alternative methods for solar power generation which don't involve conventional silicon as this can be difficult to recycle at end of use.

Benchmarking a silicon cell

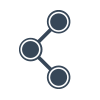

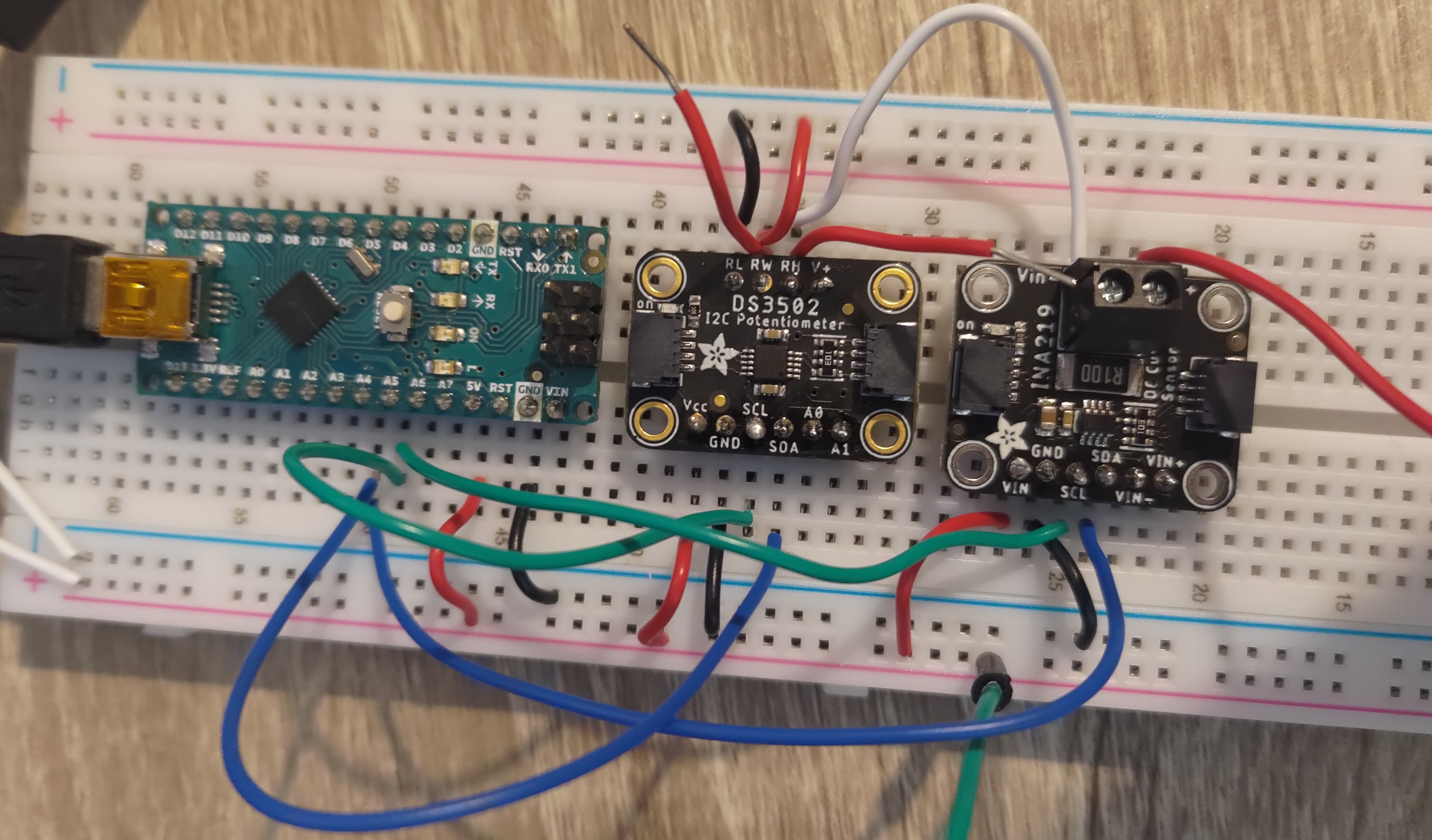

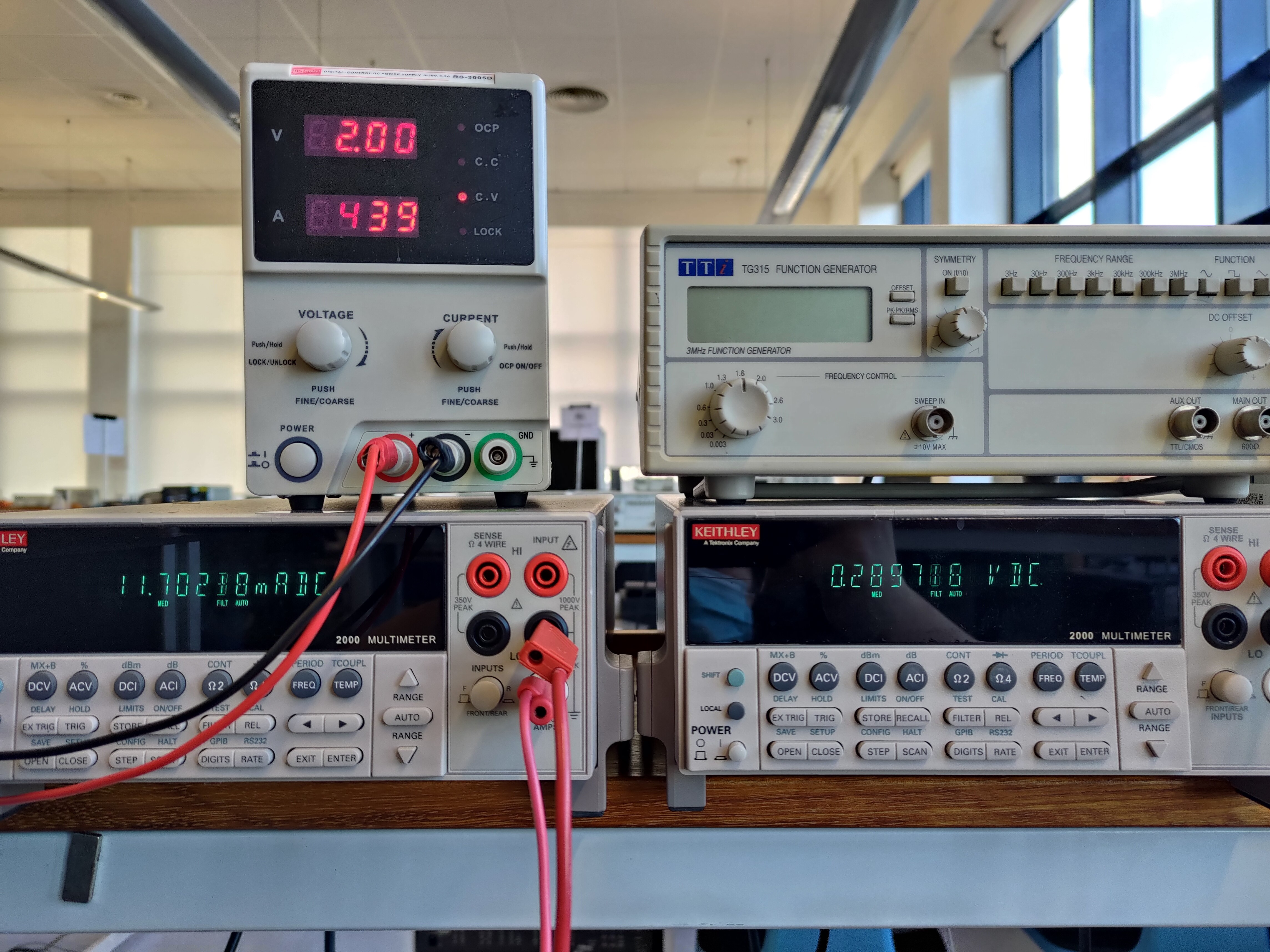

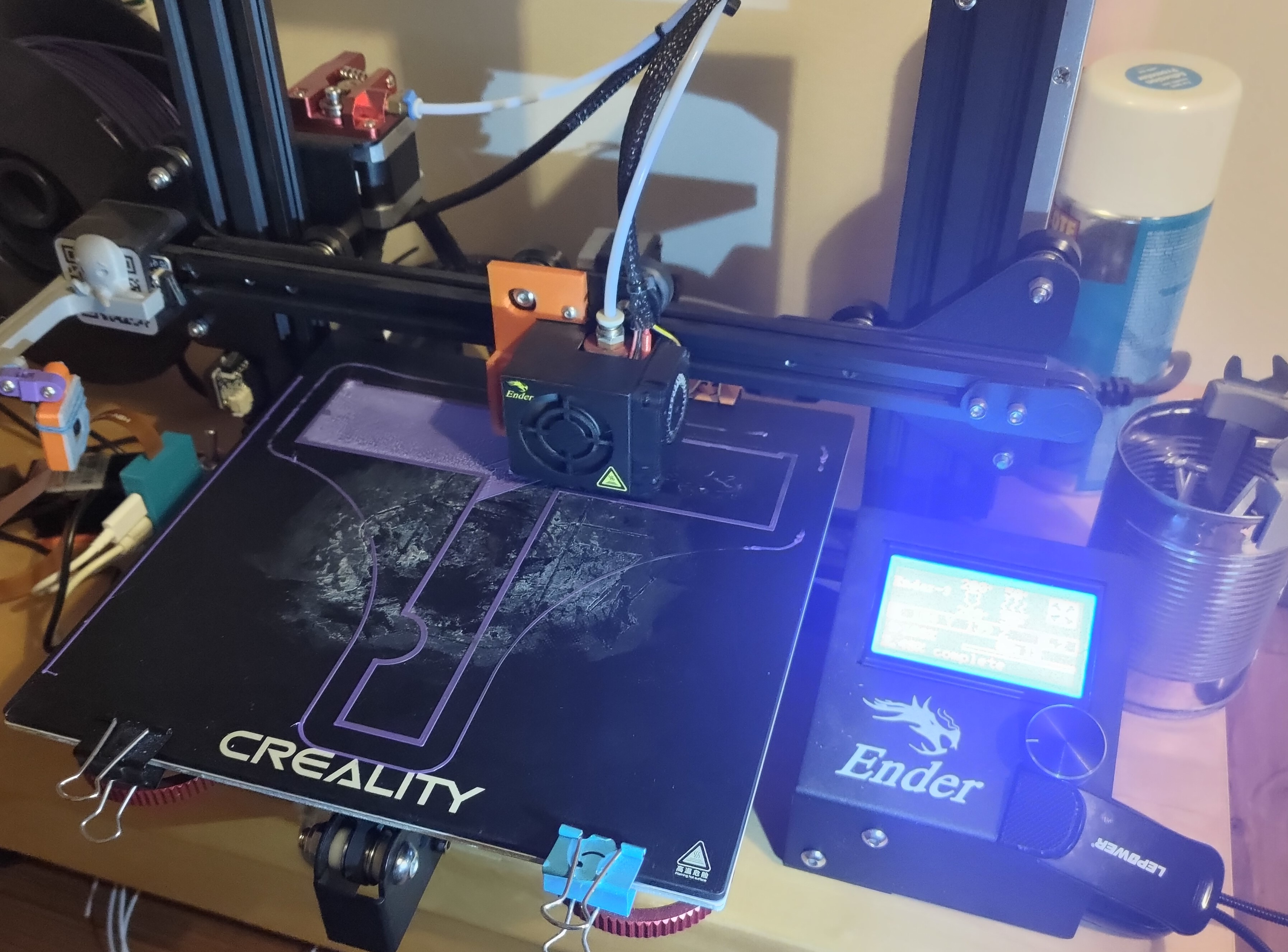

To test the cells that we would be making, a light box was setup. A standard silicon cell was then tested to get an understanding of how much power could reasonably be harnessed from the light source and to give a benchmark to compare results against. Initially the testing of cells was done using a separate voltmeter and ammeter to record the I-V curve created by the cell. This was found to be very inefficient and was difficult to reliably repeat, so I setup a test circuit with an Arduino to record the result. The Arduino project can be seen in detail here, Arduino Multimeter

Extracting the Dyes

The dyes were extracted from a range of plants, fruits and vegetables all based on success in previous research. The exact extraction method had to vary slightly based on the source of the dye but the base principle involved crushing the source in either water or ethanol and then filtering the solution.

Analyzing the Dye

With the dye extracted it was then watered down and analyzed using a spectrometer. This allowed us to see the absorption of the dye over a range of wavelengths. The absorption of the dye in the wavelengths of the sun are one of the most important properties of the dye so testing this at an early stage helped us rule out certain dye sources without making cells for them.

Making the Cells

To make the cells, a Titanium dioxide paste was made, and spread thinly onto a sheet of conductive glass. The cell was then heated on a hotplate and left to cool. The extracted dye was then carefully dropped onto the Ti02 with a pipet and left to soak in. The excess dye could then be rinsed off and the cell is left to dry. Finally a small amount of redox electrolyte solution is sandwiched between the Ti02 layer and another sheet of conductive glass, and the pieces are clamped together.

Testing the Cells

With the cells made they are then tested in the same setup as the initial silicon cell.